Why Is WPC Decking Becoming the Future of Outdoor Flooring?

2025-10-24

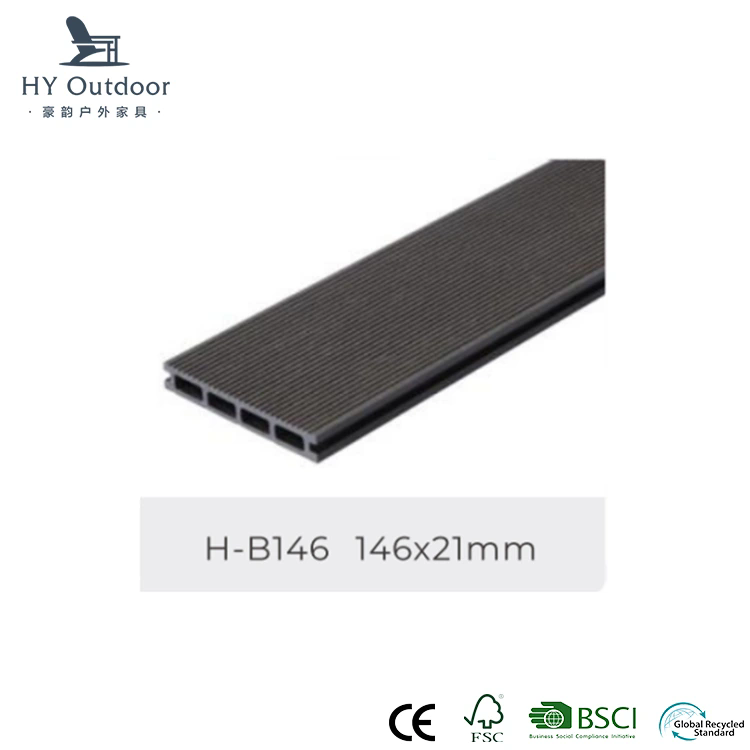

Wood Plastic Composite (WPC) decking is transforming the global outdoor flooring market by combining the aesthetic warmth of natural wood with the durability and low maintenance of modern composites. Unlike traditional timber, WPC decking is engineered from a blend of wood fibers and thermoplastic materials such as polyethylene or polypropylene. This unique composition makes it resistant to moisture, insects, and UV rays, creating a product ideal for outdoor use in all climates.

WPC decking offers a consistent appearance, minimal upkeep, and long-lasting performance—qualities that have positioned it as a sustainable and stylish choice for residential patios, commercial walkways, poolside decks, and public spaces. As eco-conscious consumers increasingly seek green alternatives, the demand for WPC decking has surged due to its recyclability, reduced deforestation impact, and long service life.

The core of this innovation lies in what WPC decking represents: a sustainable evolution in building materials. It bridges the gap between natural beauty and engineered endurance, ensuring that outdoor spaces remain both beautiful and functional for years.

Why Choose WPC Decking Over Traditional Wood?

The advantages of WPC decking extend far beyond its appealing surface. From its environmental benefits to its cost efficiency, WPC decking solves many of the challenges faced by homeowners, architects, and builders when using natural wood outdoors. Below is a technical overview of the key performance parameters that distinguish WPC decking:

| Parameter | Specification | Benefits |

|---|---|---|

| Material Composition | 60% wood fiber, 30% recycled HDPE, 10% additives | Eco-friendly and durable |

| Density | 1.3–1.4 g/cm³ | High strength and impact resistance |

| Water Absorption | <0.5% | Excellent waterproof capability |

| Thermal Expansion Coefficient | 33–55 ×10⁻⁶/°C | Stable under temperature changes |

| Slip Resistance | R11 (EN 13893 standard) | Safe in wet environments |

| Surface Treatment | Sanded, brushed, embossed, or grooved | Variety of finishes for design flexibility |

| Lifespan | 15–25 years | Long-term value with minimal upkeep |

| Recyclability | 100% recyclable materials | Sustainable and eco-conscious choice |

From the above data, it’s evident that WPC decking provides a superior balance between strength, sustainability, and aesthetic versatility. Unlike wood, it does not crack, warp, or fade quickly under sunlight, nor does it require regular staining or sealing.

Why does this matter? In traditional decking, maintenance costs and environmental concerns are major issues. WPC decking eliminates these problems by offering a low-maintenance, eco-friendly, and visually appealing alternative that retains its integrity over time.

Furthermore, WPC decking resists termites, mold, and mildew, which can quickly degrade wood in humid or coastal regions. This resilience not only extends the product lifespan but also reduces the long-term carbon footprint of outdoor construction projects.

How Does WPC Decking Contribute to Sustainable Living and Future Design Trends?

In recent years, the global construction industry has shifted its focus toward sustainable and low-carbon materials. WPC decking is at the forefront of this movement, supporting both green architecture and circular economy goals. Here’s how WPC decking contributes to the future of outdoor design:

-

Recycled and Renewable Resources

WPC decking utilizes waste wood fibers and recycled plastics, helping reduce landfill accumulation and deforestation. This makes it an environmentally responsible material aligned with international sustainability standards such as LEED and BREEAM. -

Energy-Efficient Production

Manufacturing WPC decking consumes less energy compared to traditional hardwood processing, minimizing environmental pollution and energy waste. -

Extended Life Cycle

Its resistance to moisture, UV rays, and biological degradation ensures that WPC decking outlasts conventional timber, reducing replacement frequency and resource consumption. -

Innovative Surface Technologies

Modern surface treatments—such as 3D wood grain embossing, co-extrusion technology, and anti-slip coatings—offer an authentic wood-like texture with enhanced performance. -

Architectural Flexibility

WPC decking can be customized in various colors, finishes, and profiles, making it suitable for minimalist modern villas, resort pathways, or commercial terraces. The ability to integrate with aluminum or stainless-steel substructures enhances both strength and aesthetic diversity.

How will WPC decking shape the future?

Future outdoor flooring trends are gravitating toward eco-designs that harmonize with the environment. WPC decking fits perfectly within this vision—its versatility allows it to blend seamlessly with greenery, water features, and contemporary architecture. As more nations adopt carbon-neutral targets, the use of recyclable composite decking will continue to rise, leading to a significant decline in tropical timber consumption.

Additionally, emerging smart decking systems—integrating lighting, sensors, and temperature control—are being designed using WPC materials due to their compatibility with embedded technologies. This trend points toward smart, sustainable outdoor environments that combine comfort, efficiency, and beauty.

Common Questions About WPC Decking

Q1: How long does WPC decking last compared to traditional wood?

A properly installed and maintained WPC deck can last between 15 and 25 years, whereas traditional wood decking often requires major repairs or replacement within 5 to 10 years. The superior weather resistance of WPC decking helps prevent warping, cracking, or fading, even under continuous exposure to sunlight and rain. Its long lifespan results in lower total ownership costs, making it a smart investment for both homeowners and commercial developers.

Q2: Is WPC decking suitable for hot or humid climates?

Yes. WPC decking is specifically engineered to perform well in humid, tropical, and coastal regions. Its low water absorption rate and anti-slip properties make it ideal for pool decks, marinas, and gardens. The co-extruded protective layer also prevents color fading and surface damage under UV exposure, ensuring consistent performance in harsh weather conditions.

Why Zhejiang Haoyun Is Leading the Way in WPC Decking Innovation

Behind every great product is a manufacturer committed to quality, innovation, and sustainability. Zhejiang Haoyun, a leading WPC decking manufacturer in China, exemplifies these values through its advanced production technologies and rigorous quality control.

Haoyun’s WPC decking lines are developed using state-of-the-art extrusion processes, ensuring precise dimensional stability, uniform surface finishes, and long-term performance in diverse climates. The company emphasizes environmentally friendly practices by incorporating 100% recyclable materials and optimizing production efficiency to reduce emissions.

Zhejiang Haoyun continues to innovate with co-extrusion WPC decking, anti-UV formulations, and enhanced slip-resistant textures, meeting the growing demands of international markets. With global distribution networks and technical support, Haoyun products are trusted by architects, builders, and distributors worldwide.

As outdoor living trends evolve toward sustainability and design sophistication, Haoyun remains at the forefront of this transformation—offering not just products, but complete outdoor solutions that harmonize with modern lifestyles.

For more information about WPC decking options, technical details, or project consultations, contact us today to explore how Zhejiang Haoyun can help bring your outdoor vision to life.